Manufacturing of plastic parts simulated.

Pezy Group has a small Moldflow® team that can run simulations to check the manufacturability of plastic parts. In this article, we give an introduction about how Moldflow® can be a useful tool in the development process.

Moldflow® team bij Pezy Group

What is Moldflow®?

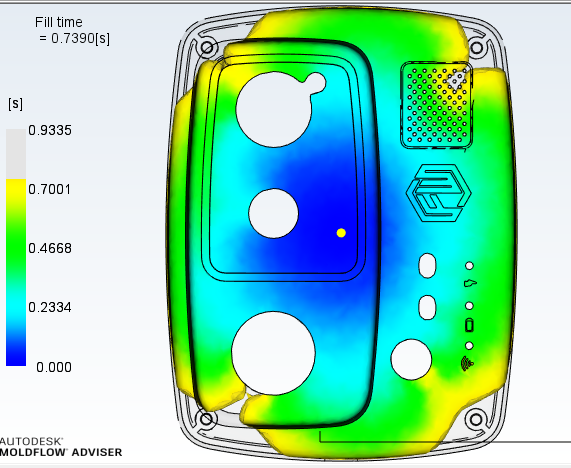

Autodesk Moldflow® is a simulation program in which the process for manufacturing plastic parts can be simulated.

How do we integrate Moldflow® into our development process?

Moldflow® can be used to check whether a part is manufacturable (wrt filling) and to check which effects (trends) exist on dimensions, sink marks, and warpage.

Traditionally the tool was created for/ used by manufacturers, to design their tools or optimizing their processes. The simulation of the parts can, however, also be used as a development tool. Some details in the construction can have a very large effect on manufacturability. Changing and modifying those details is easier during the setup of the construction than it is to make changes once the tools have been finalized and the production has started.

What are the limits of Moldflow® within Pezy Group?

With Moldflow® a prediction can be made of trends and factors that influence these effects. The exact dimensional changes cannot be determined. This tool can make very extensive analyses. However, within Pezy we don’t use the simulation for setting up detailed analyses of the exact mold layout and process parameters. The product geometry is the basis of our simulation, with the assumption that the cooling and injection are optimal. Main factors and risks can be flagged, but in the end, the supplier determines the best mold and process setup.

How can Moldflow improve the development process?

Reviews are part of the development process. Sparring sessions, FMEAs, evaluations, involving experts and making sure that controls of products and processes are in place, can improve the quality. Critical issues need to be determined and addressed early.

For critical plastic parts, Moldflow® can add value to these reviews by making a quick analysis on the part status. In the end, all parts need to be manufactured, this way critical details can be determined before the parts are finalized. Even as early as in the concept phase this can be of value! Thickness issues, inclusion, and filling problems can be solved by changing the part split or assembly architecture. This change is easier to adapt when the interfaces between the parts are not yet fixed. In the engineering phase, parts can be adjusted during optimization loops. During the final evaluation, a full simulation can be done, which shows if the product can be produced within certain boundaries. This is why within Pezy Group Moldflow® is a valuable tool in the development process.