Step by step towards circular products

Expertise

Circular product development

PolyCE is a European Commission funded project that has taken up the challenge of creating a more sustainable life cycle of e-plastic materials. Pezy Group was part of the PolyCE consortium. This consisted of 20 expert organizations working together to significantly reduce the use of virgin plastics and improve the use of recycled plastics in new electronics applications. Experts from the PolyCE consortium share the latest guidance on circular insights.

Download the PolyCE reader on circular guidelines now.

CIRCULAR PRODUCT DEVELOPMENT

Success with and in the chain

By using more recycled and renewable materials as raw materials for new products, we create a circular product in a circular economic model. To successfully achieve this, all players within the plastics value chain are needed. Pezy Group helps companies to break the traditional take-make-waste design process.

MAKING AMBITIONS INTO REALITY

Our Drop-in method

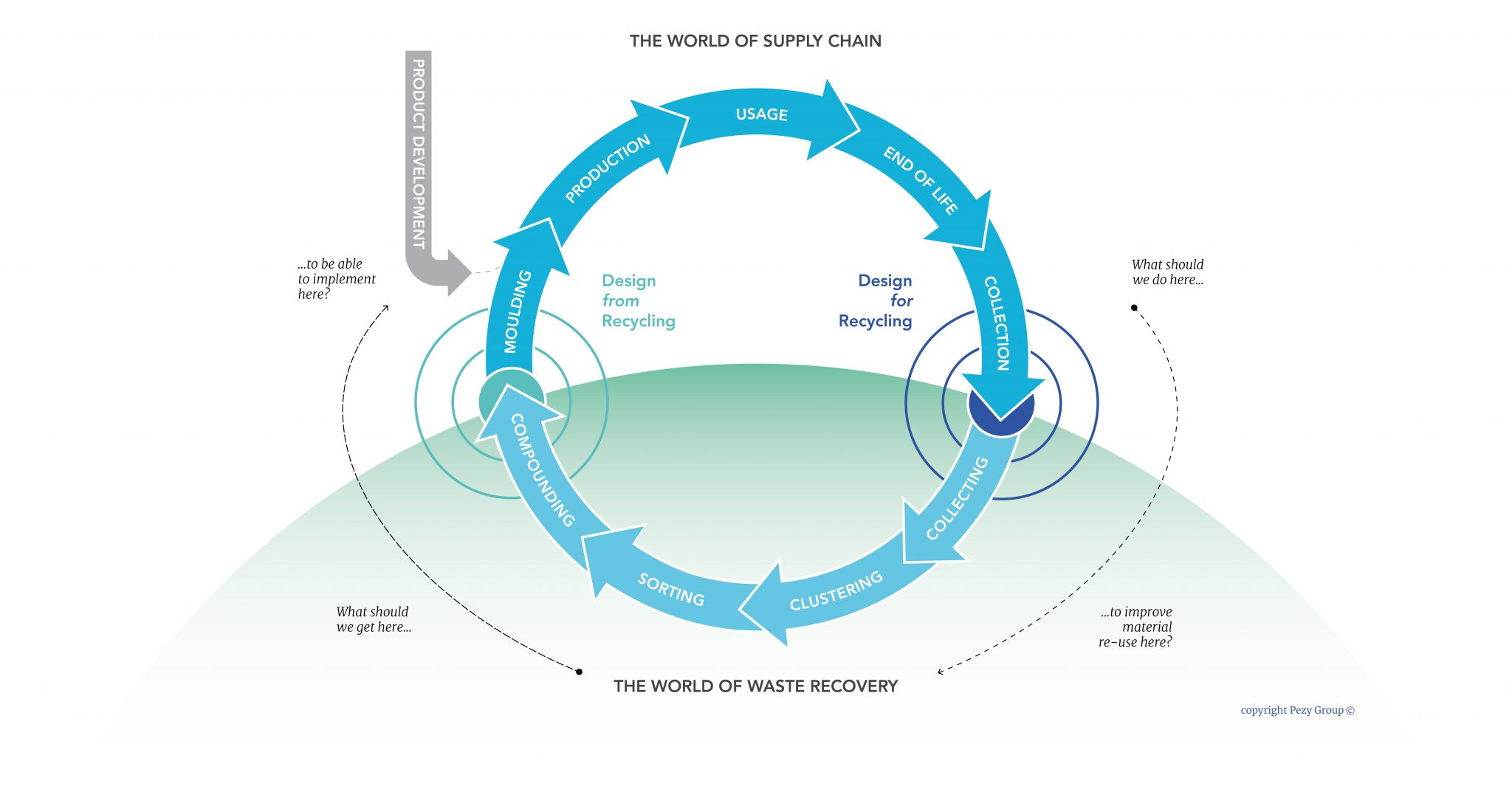

Our design process is aligned with the entire plastics value chain. We design products that are suitable for recycling (Design For Recycling) or based on recycled materials (Design From Recycling). We apply these materials in a way that keeps them as high quality as possible throughout the cycle of use and reuse.

With the ‘Design for Recycling’ approach, it is possible for the waste processors to process your plastic product into a raw material that can be reused for new quality products.

With the ‘Design from Recycling’ methodology, we deliver your design of a quality product made from recycled plastics. By using these materials we close the chain and create less waste. The challenge here is to meet all the requirements for the material during and after the product’s lifetime. The knowledge and experience with ‘virgin’ plastics is no longer applicable here, as the properties of recycled plastics are still largely unknown. With more than 10 years of experience in the application of recycled plastics, we have developed a pragmatic Drop-In methodology. With this methodology we deliver your design of a quality product from recycled plastics.

Cases in circular product development

APPROACH

Three crucial design tools

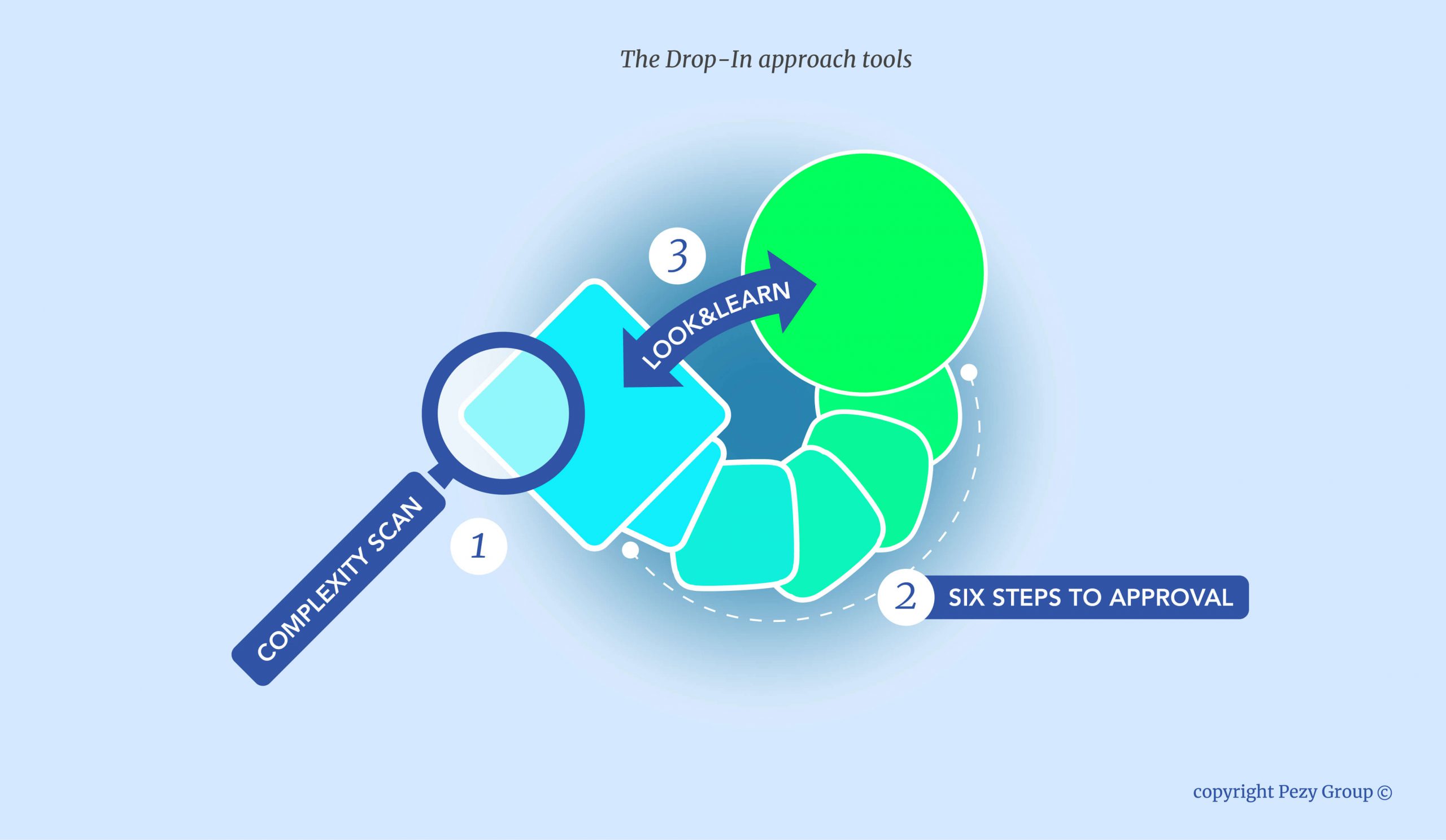

The Pezy Group Drop-in method includes three main tools;

- Complexity Scan; how complex would it be to make your product circular? Which products or parts are the most interesting to start with?

- “Six steps to Approval”. In six steps we go from material selection to release of your product designed on the basis of recycled plastics with the right properties.

- Watch & Learn. At each step, we demonstrate the performance of the material in aesthetic and mechanical terms using injection mold tests and demonstrators.