An innovative and smart product

INLINE INSPECTIONPARTNER

Innovative microsensortechnology

INGU’s Pipers® solution, innovative micro sensor technology and advanced data analytics, provide condition-critical data to optimize pipeline integrity programs. Free floating Pipers® keep operators in oil, gas, and water on top of wall condition, deposits and leaks in all pipelines, regardless of location, condition, materials or configuration, free of downtime and with a self-serve model. Headquartered in Calgary (Canada), INGU is the inline inspection partner for many of the worlds’ leading oil and gas companies.

Collaboration INGU and Pezy Group

The collaboration with Pezy Group was established in 2012. Back then, INGU faced a major challenge. They wanted to develop and launch a completely new type of product. In order to achieve this, a lot of research had to be done. For example, into the possibilities for a robust plastic housing and its integration with compact electronics and sensors. INGU was therefore searching for a product development partner. More specifically, a company with an innovative character that had a lot of experience in the field of product development and plastics. They choose to collaborate with Pezy Group.

Product development

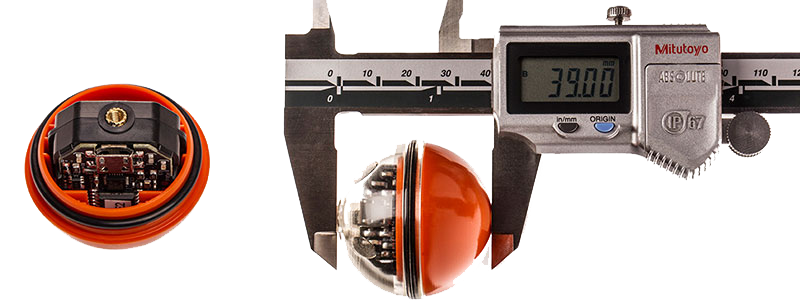

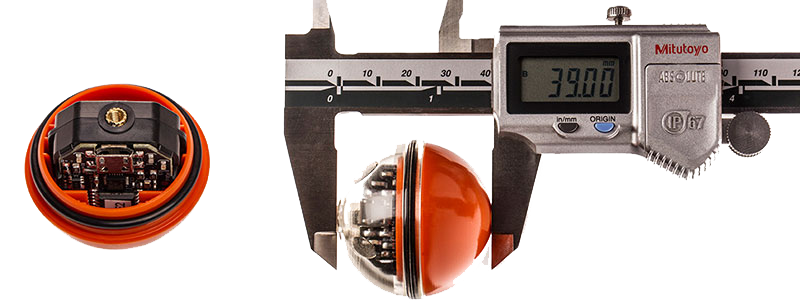

The housing of the new product Pipers® had to withstand extreme pressure, temperature and be chemically resistant. The housing also had to be as light as possible. Therefore, experiments for buoyancy could be carried out by means of weights. The limited free space within the housing had to be used for delicate electronics and sensors that had to be readable.

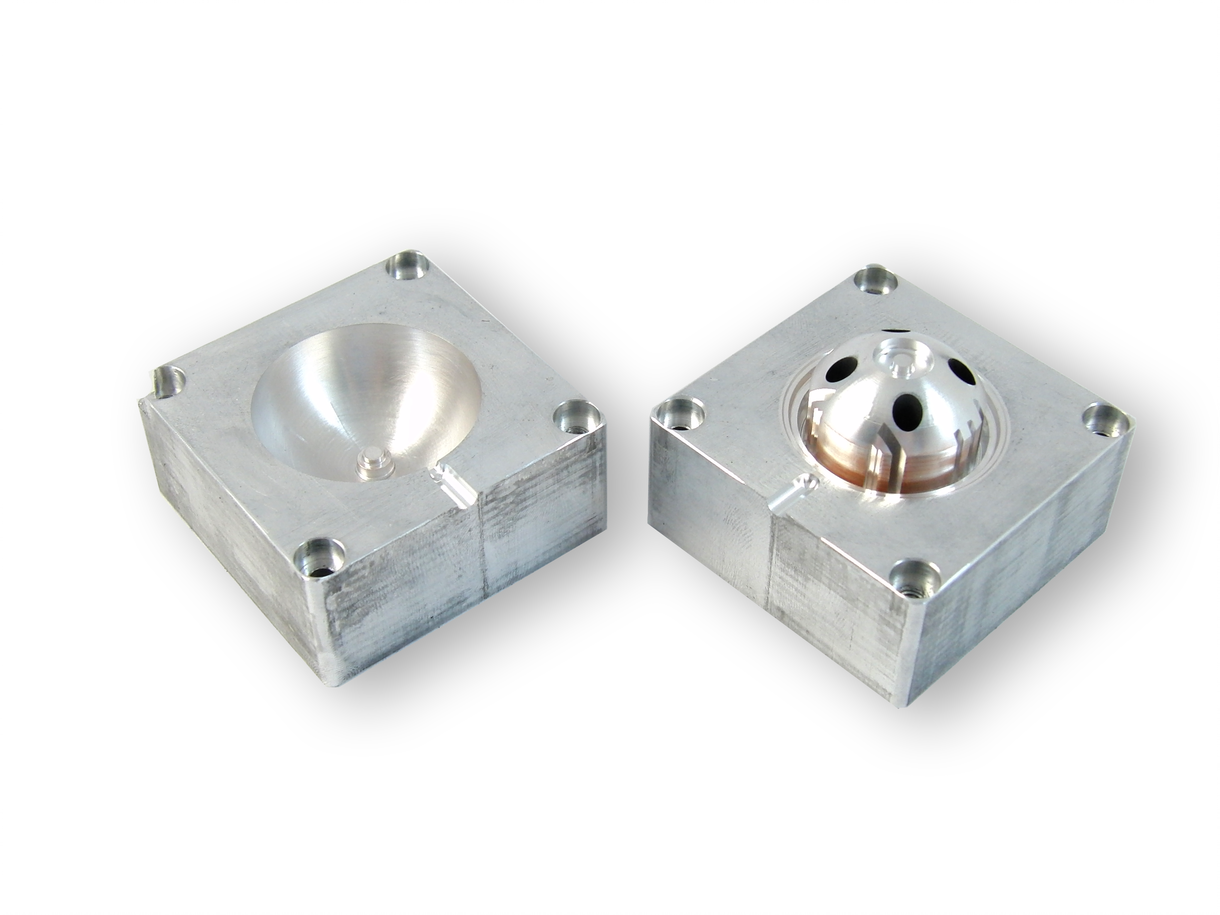

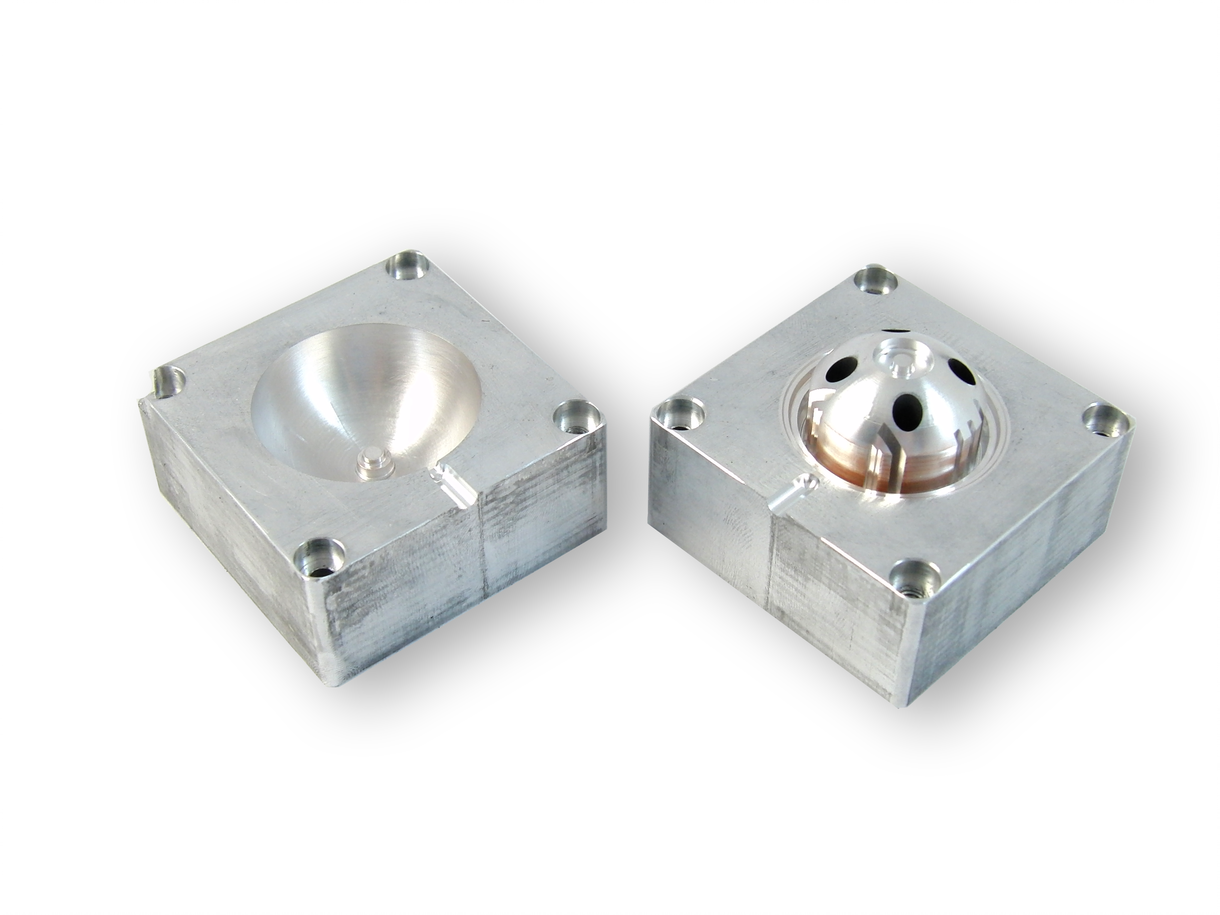

A material selection was carried out on the basis of these requirements. The selected materials had been characterized by Pezy Group and the output of these tests was used to simulate the harsh conditions in the field of pressure and temperature. These simulations resulted in a design that was, within a short period of time, converted into fully-fledged molds and products in the Pezy Group’s mold making and injection molding shop. To prove that the measurements and simulations corresponded to reality, the housings were tested in a pressure vessel under extreme conditions. After the successful completion of the tests, the manufacturing of the housings started.

John van Pol

CEO Ingu

“During our collaboration, it became clear that Pezy is one of the few parties that has the specific knowledge in-house to develop a product that meets the high standards we set for our housing. As the production volume increased, we started looking for an alternative partner in Canada, but Pezy remained the best choice.

Their specialist knowledge ensured that, we were well aware of the possible risks. Therefore, there were no surprises during the product development process. In addition, Pezy Group always looks for new possibilities. Every time we try to extend the application range of the Pipers®, Pezy knows how to come up with a solution. In short, their highly competent team consistently supported our product development, for us Pezy Group is a great partner to work with.”